PRODUCTS & APPLICATION

STORAGE TANK

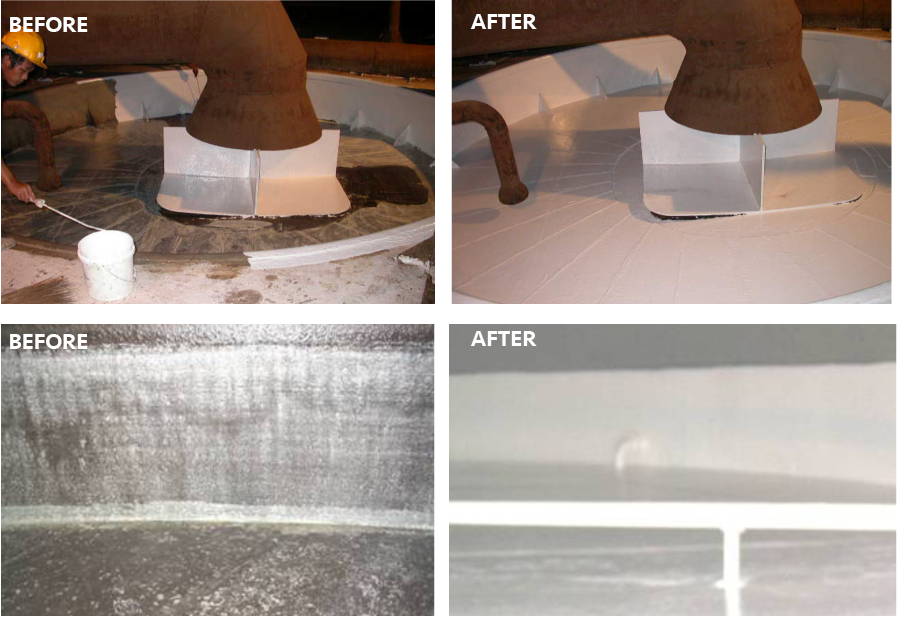

Focus 1: Tank Internal Protection

Internal lining to protect against cession for storage tank internal

Focus 2: Tank Roof Repair

Tank roof/tank shell was suffering sever corrosion. Repair was carry online without hot work. The tank was patch with composite material to extend life cycle.

Tank internal roof suffering corrosion. Plate cold bonding method to carry out the repair to avoid hot work

- In many cases, tank bottom linings have proven to be an effective method of preventing internal corrosion of steel tank bottoms.

- Also to maintain product purity

- Can be applied for spot repair of bottom plate damage

- Easy to maintain, cleaning, inspection

- Save cost, easy to apply, more safe to work compare with tank re-bottoming

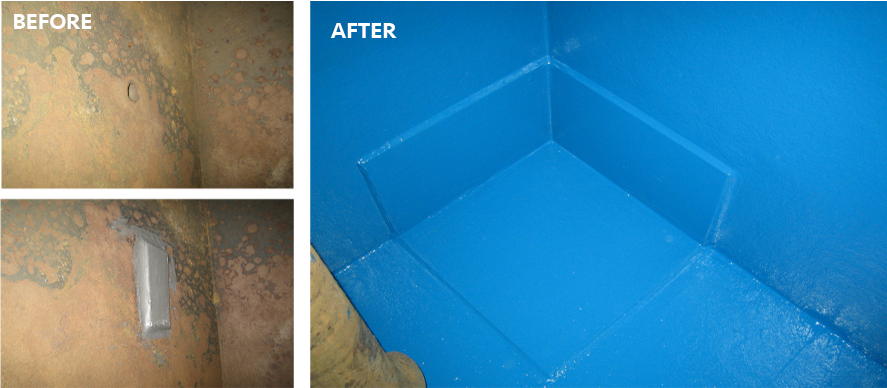

Focus 3: Tank Leak Repair

Internal Tank base worn and pitted was found. Plate patching without hot work to repair tank internal. A layer of protective coating to protect from corrosion

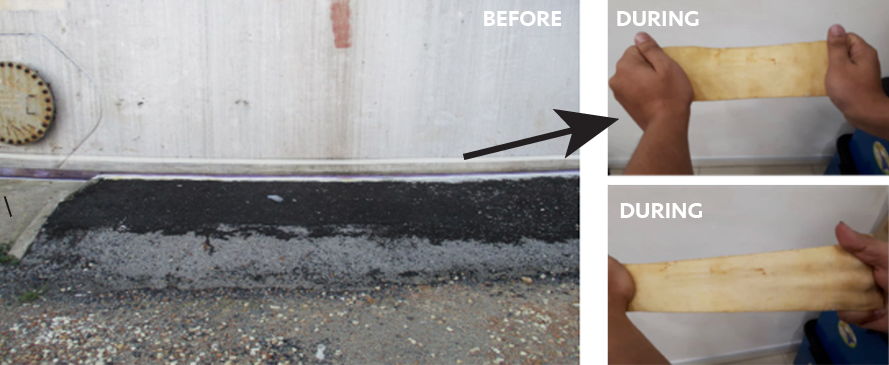

Focus 4: Tank Base Protection

Tank base external: Storage tank base annular plate suffering corrosion then leak was found due to no protection leak was found due to no protection.

An flexible solution to protect water ingression on tank annular plate and absorb tank base annular movement.

Top coat to protect against UV resistance