EQUIPMENT & PRODUCTS

MONTIPOWER BRISTLE BLASTER

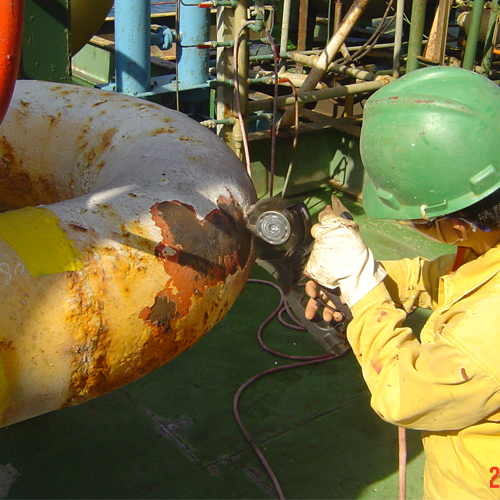

What is the Bristle Blasting Process?

Bristle Blasting is a new process that uses a specially designed rotary bristle tool for achieving both corrosion removal and an anchor profile.

GROUNDBREAKING AND CUTTING-EDGE

The world’s only hand power tools that can “sandblast”. The patented technology removes corrosion and coatings quickly and thoroughly. At the same time, the Bristle Blaster® and MBX® create surface preparation grades comparable with Sa2½ (SSPC-SP 10/NACE No. 2) to Sa3 (SSPC-SP 5/NACE No. 1) and roughness levels of up to 120 µm Rz.

NEW INNOVATION

The patented Bristle Blaster® is the first hand-held brush belt system in the world that produces a quality of surface roughness and a result comparable to that achieved by ‘sandblasting’. The Bristle Blasting process is a new innovation that both removes corrosion and generates an anchor profile by using a specially designed rotary bristle tool. This tool consists of wire bristle tips that are bent forward and dynamically tuned to a hand-held power tool which operates at approximately 2,500 rpm.

MECHANICAL PRINCIPLES

Bristle tips are designed to strike the corroded surface with kinetic energy that is equivalent to standard processes that use grit blast media. Immediately after the bristle tips strike the corroded steel surface, they retract (i.e., “rebound”) from the surface, which results in both corrosion removal and a micro-indentation that exposes fresh surface. Consequently, surfaces that have been treated by the Bristle Blasting tool have a texture and visual cleanliness that mimics those obtained by traditional grit blasting processes.

The different power tools of MontiPower® are a phenomenal breakthrough when it comes to ‘blasting without grit’. The patented characteristics of the Bristle Blaster® and the MBX® formed the basis of new surface preparation product ranges.

Bristle Blaster® Range

Bristle Blaster® Electric

Bristle Blaster® Electric

The Bristle Blaster® is a specially designed rotary bristle tool that both removes corrosion and generates an anchor profile.

Bristle Blaster® Electric

Bristle Blaster® Electric Double

Bristle Blaster® Electric Double

Double the Power! The Bristle Blaster® is a rotary bristle tool that both removes corrosion and generates an anchor profile.

Bristle Blaster® Double

Bristle Blaster® Cordless

Bristle Blaster® Cordless

The new cordless technology for the Bristle Blaster® including the Safety switch. It includes the anti-vibrating handle and a new robust fronthead.

Bristle Blaster® Cordless

Bristle Blaster® Pneumatic

Bristle Blaster® Pneumatic

The Bristle Blaster® is a specially designed rotary bristle tool that both removes corrosion and generates an anchor profile.

Bristle Blaster® Pneumatic

Bristle Blaster® Axial

Bristle Blaster® Axial

The patented characteristics of the Bristle Blaster® form the basis of new innovations wich are now being used to enter new markets.

Bristle Blaster® Axial