PRODUCTS & APPLICATION

THERMAL BARRIER COATING

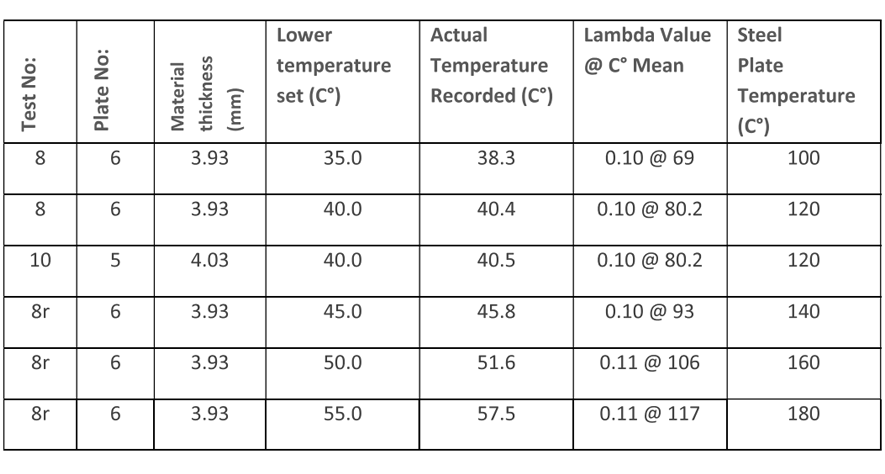

Independently tested by Gearing Scientific

- Proven to reduce surface temperature

- Proven to have insulating qualities

- Reduces heat loss by 60% compared to bare steel pipe

- Applied to hot and cold surfaces

- Good chemical and corrosion resistance

- Reduced downtime of production areas

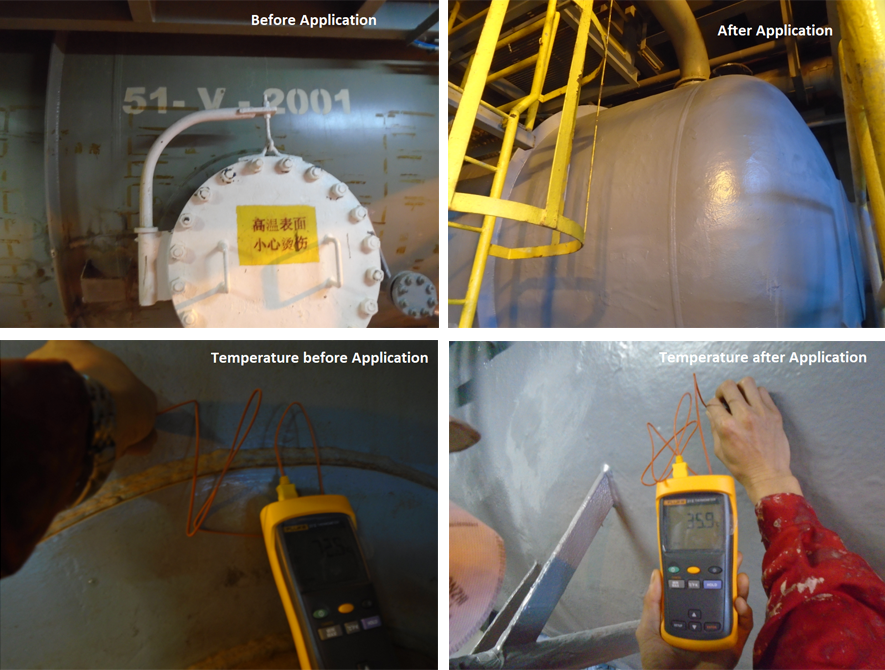

561 Thermal Barrier was applied at a wet film thickness of 4mm onto the hot surface (95℃). The film thickness was built up with multiple coats of the material. Once cured the surface temperature was measured at 45℃.

Apply external coating material Resimac 561 to the Degasser & Close drain vessel on PY5-1A Platform and a Close drain vessel on PY4-2A to achieve the insulation effort. The building up coating DFT will be up to 4mm, the surface temperature will redure from 72℃ to 35℃.